What We Do

EMSG specializes in volume manufacturing, including prototyping for clients in a range of industries. We can provide the following industrial PCB assembly services:

PCBs are used in various military applications, such as firearms, vehicles, communication equipment and computers. Considering these devices may be subjected to extreme conditions, ensuring the PCBs used are durable and reliable is crucial. Regardless of the high temperature or oxidation levels, the devices must function. As such, it’s best to use materials such as aluminum, copper and laminates where necessary.

PCBs have wide military applications, such as:

Besides defense, PCBs have vital applications in other government projects, including the following:

EMSG specializes in volume manufacturing, including prototyping for clients in a range of industries. We can provide the following industrial PCB assembly services:

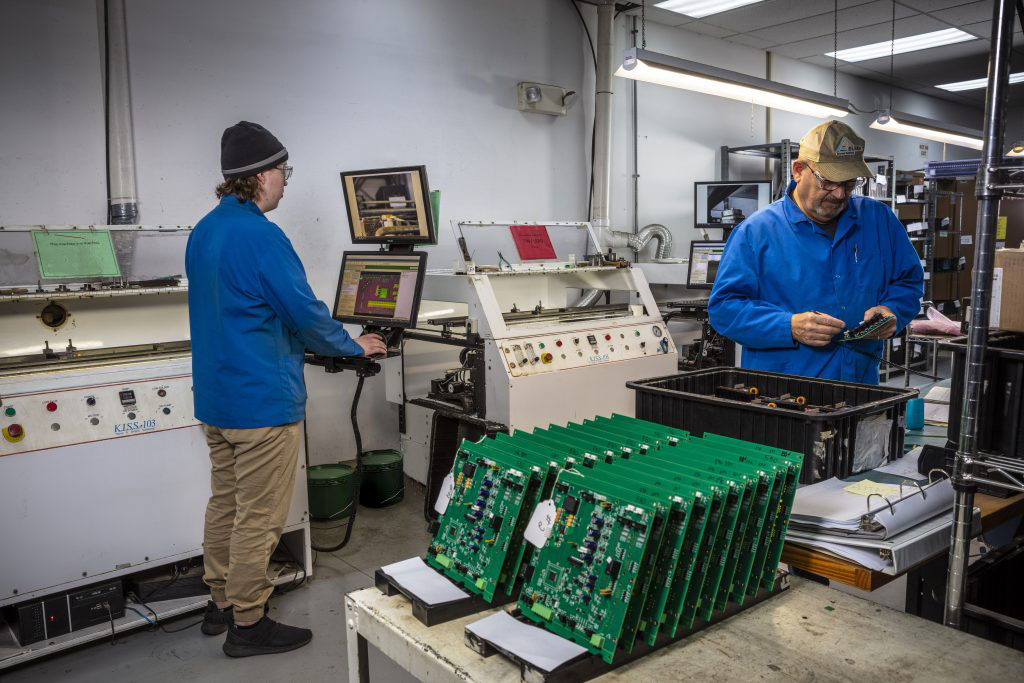

SMT is the technology of choice for many industrial and commercial applications. EMSG assembles SMT printed circuit boards to the IPC-A-610 standard in both leaded and ROHS technologies. We have equipped our facility with a variety of screen printing and component placement machines as well as x-ray testing and other devices to ensure an exceptionally high standard of quality control.

Thru-hole mounting is an older form of industrial PCB assembly that many demanding commercial applications still use today. It is more time-consuming than SMT assembly but produces circuit boards that are more durable and better-equipped to withstand shock and vibrations. Thru-hole circuit boards are frequently used in military and aerospace devices as well as industrial equipment. EMSG provides both fully and semi-automated thru-hole assembly services for mid to high volume runs.

EMSG can also provide box build assembly and other mechanical systems integration services necessary to bring your product to market. We can source enclosures and wiring harnesses or manufacture a custom product to your specifications. We can also provide burn-in and testing services as necessary as well as drop shipping to your end customer. Working with us, you’ll enjoy lower overhead costs, faster turnaround times and less hassle overall while maintaining product quality and consistency.

We visually inspect all PCBs under magnification for surface-level defects and other concerns. Depending on your requirements, we can also use automated optical inspection technology to identify lead- and component-level errors such as missing or incorrect devices, polarity reversals or insufficient soldering. We can also provide in-circuit and functional testing if requested. Our engineers can develop a customized quality control routine for your product.

Consider outsourcing your manufacturing to EMSG. We have worked with a range of industrial and commercial clients in the past. We have the flexibility to alter our services to meet your business and technical requirements. With our expertise in industrial PCB assembly and our internal box build and testing capabilities, we can perform all work in-house and oversee each stage of the process for greater transparency and accountability.

EMSG is trusted and renowned among high-performing sectors with almost three decades of experience. Our professionals are ready to meet your unique requirements and help you maintain compliance. Do you want to learn more about our products and services? Contact us today!