Our Facilities

20,000 square feet with 4,000 square feet of office/engineering area

Office

Computer network system running Visual Manufacturing, including the following: Inventory Management, Production Scheduling, Costing, Sales and Invoicing, Bills of Materials, Accounting, and Purchasing.

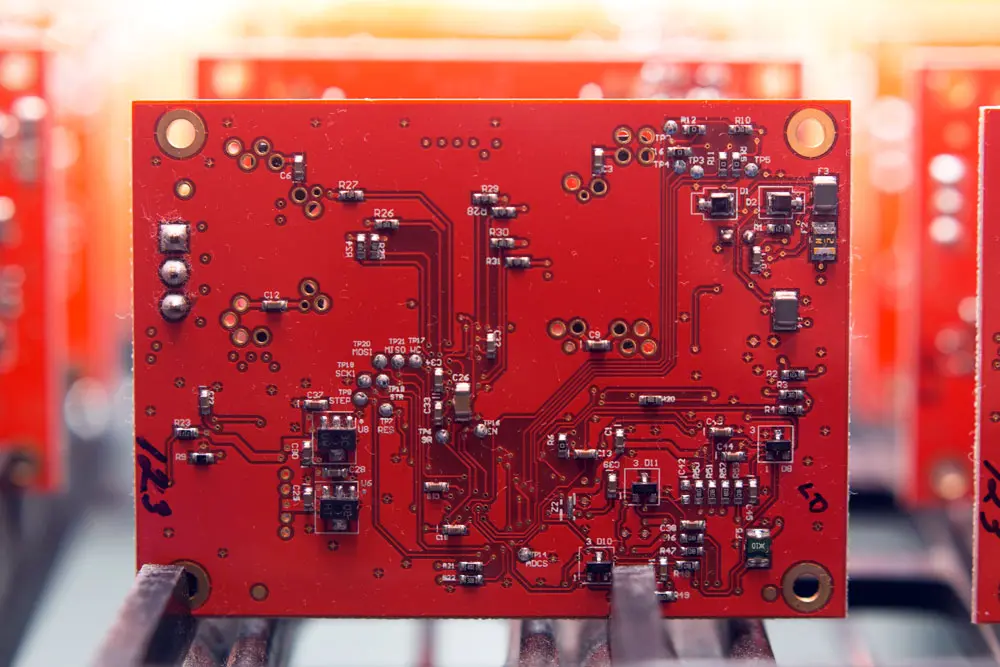

Prototyping and Custom Design Preparation for PCBs

The process our engineers use to set components can be automated for high-volume orders. However, specialized medical equipment often calls for more customization. Our team is fully equipped to meet any unique requirements you have as we assemble your circuit boards in small batches with superior attention to detail.

At EMSG, we use exclusive PCB design software to ensure that each PCB component is positioned for maximum efficiency and quality assurance. After prototyping, PCB assembly is our next step.