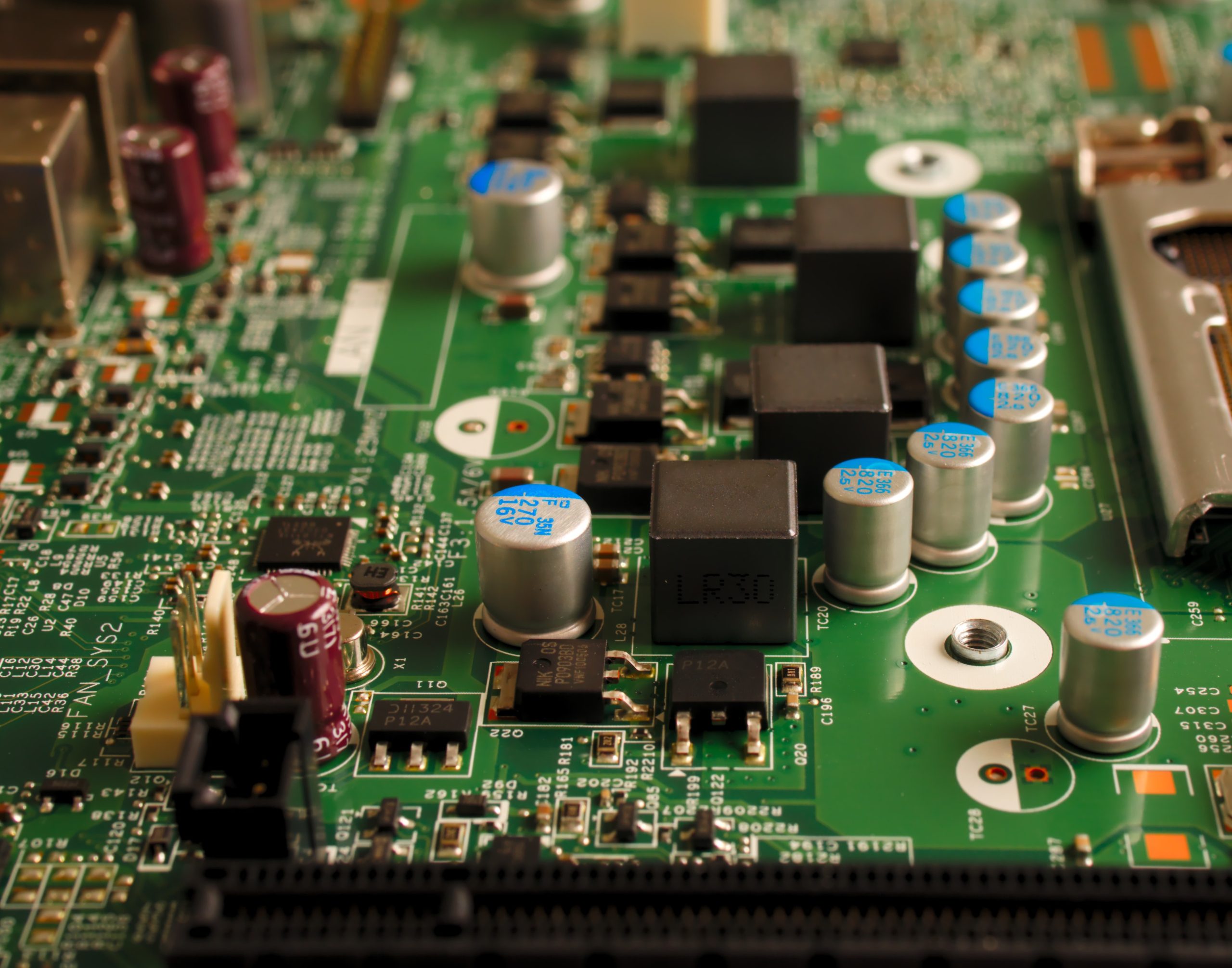

Medical Device PCB Assembly and Electronic Contract Manufacturing

Medical device industry manufacturers — including those that manufacture high performance electronic medical devices and other electronic devices — are required to meet strict sanitary and quality control benchmarks. If your device includes printed circuit boards or other electronics, this presents an additional challenge. The best way to minimize risk is to work with a medical device circuit board manufacturer that has experience in your industry.

EMSG has been providing the medical equipment industry with PCB electronic assembly services and contract manufacturing since 1995. We follow all relevant best practices during the circuit board assembly process. As a result, we are an electronic medical device manufacturer that is uniquely equipped to help you bring to market reliable pumps, robotics, power supplies and other medical devices.

Keep reading to learn more about our services or contact our office for assistance.