Companies outsource electronics manufacturing due to its convenience, cost-effectiveness and time-saving capabilities. However, there are some common roadblocks to address. These challenges concern:

The good news is there are ways to navigate these challenges and achieve your goals. We’ll dive into the challenges you’ll likely face in contract manufacturing in the electronics industry. Then, we’ll look at ways to resolve them.

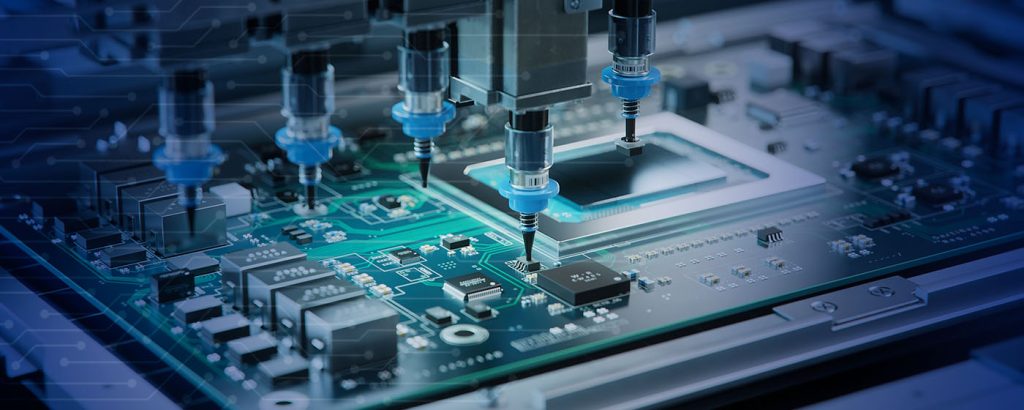

In contract manufacturing, companies outsource electronics manufacturing to specialized third parties. The third parties — contract manufacturers — have the infrastructure to produce the components according to defined specifications. They also comply with established standards and best practices. Contract manufacturing services may include:

Industries that benefit from contract manufacturing include:

The electronics sector has widely adopted contract manufacturing for many reasons:

While outsourcing manufacturing is incredibly beneficial for electronics companies, these businesses may still encounter challenges along the way. Here are seven common examples:

Ensuring consistent quality across large volumes of electronic components can be challenging. This is often due to the vast differences in materials, processes and equipment. Quality issues can result in significant financial and reputational damage unless properly handled.

Manufacturers must implement strict control processes and standards. They must conduct regular audits and inspections throughout the process. Quality management systems can help track quality metrics. When choosing a manufacturer, check if they have certifications like ISO 9001 — an internationally recognized standard for quality control.

Intellectual property is legal ownership and rights derived from creations. For example, if a company invents a product, it can get a patent that gives it exclusive rights. Sometimes, contract manufacturers gain access to such sensitive information and proprietary technology. They may steal intellectual property or use it without due authorization.

You can solve this problem by executing contracts. The contract must state who owns the intellectual property and the rights of each party. It’s also essential to include a non-disclosure agreement (NDA). An NDA can prevent the manufacturer from sharing confidential information. Access to sensitive information must be limited on a need-to-know basis. It’s also vital to implement secure data transfer protocols.

Contracting companies and manufacturers must comply with regulations and industry standards. These laws often concern product safety, environmental protection and data security. Noncompliance can result in legal sanctions and lawsuits, which can affect your reputation and customer trust. Penalties can also lead to financial losses.

Choosing a manufacturer in the same region can be helpful because they would likely be familiar with the local laws and practices. This also allows you to observe the production process for compliance. You can correct deviations faster than when dealing with an overseas company.

The best third-party companies stay informed about the changes in law. They train their employees and conduct regular compliance audits to identify gaps.

Most supply chain issues involve component sourcing, inventory management and transportation. These disruptions can affect delivery times and production schedules. Companies end up incurring significant costs and losing customers’ trust.

Partnering with onshore manufacturers can eliminate most of these supply chain issues. This strategy reduces shipment costs and transportation times. It also helps you gain greater control over the manufacturing process. Choose a manufacturer with access to key vendors to avoid shortages and delays.

Effective communication and coordination are essential for a successful operation. Miscommunications can cause errors, leading to production inefficiencies, quality issues and missed deadlines.

As a result, many contracting companies turn to local manufacturers. This strategy eliminates language barriers and geographical constraints. Manufacturers also provide regular updates, keeping customers informed throughout the production process.

Balancing cost considerations while maintaining quality standards can be challenging in contract manufacturing. Fluctuations in raw material prices, labor costs and currency exchange rates often affect production costs and profitability. Over time, growth declines as companies cannot scale as expected.

Contracting companies can outsource production to local manufacturers. This reduces costs in areas like transportation and storage. You can also negotiate pricing agreements that provide cost predictability and transparency. Finally, compare prices when choosing a manufacturer, but do not comprise quality. A cheap product may seem beneficial, but it will likely cost you more in the long term.

Most companies partner with third-party manufacturers so they can scale according to demand. However, some contract manufacturers are unable to adjust operations to accommodate these fluctuations. This prevents them from delivering on their promises.

As a pro tip, investigate the contract manufacturer’s capabilities before hiring them. Assess their certifications and performance history. Explore their track record in handling different demands and unexpected disruptions. Conducting due diligence helps you learn more about the manufacturers and their competencies.

Technological advancements are changing the contract manufacturing landscape. Here are some industry trends:

EMSG is a full-service printed circuit board (PCB) assembly company serving businesses in and around Pennsylvania. We deliver high-standard work with quick turnaround times.

Our world-class facility and competent professionals can perform multiple electronic manufacturing services and exceed your expectations. We handle even the most complex manufacturing tasks like creating chips for AI servers.

Whatever your unique industry needs and project specifications, we’re ready to work with you. Contact us now to learn more!