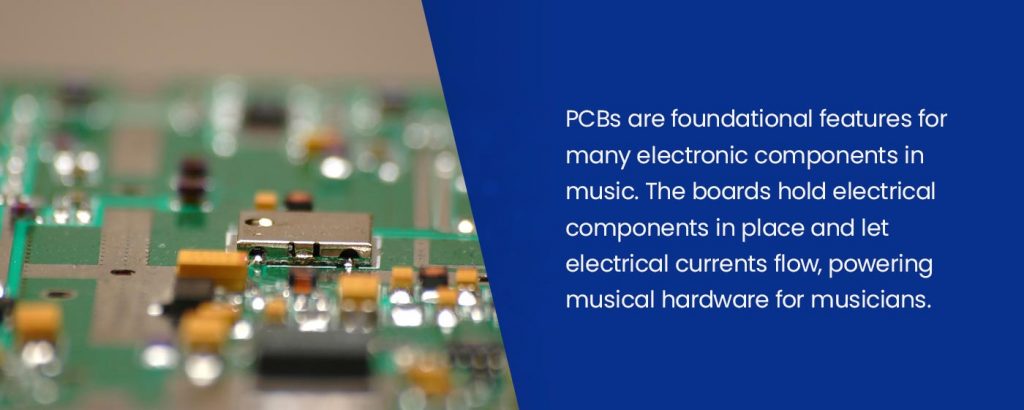

Printed circuit boards (PCBs) are surfaces used for mounting electronic system parts. Seen as the building blocks of electronic devices, they consist of insulating layers and can feature single or multilayer surfaces. PCBs help keep electric components organized and provide reliable electrical components between terminals. Each layer features a pattern of conductors that creates electrical connections.

PCBs are essential in a wide range of products and industries, from medicine to transportation. Many professionals in the music industry use PCBs regularly. From circuit boards to amplifiers, PCBs allow many musical electronics to function.

Read on for more information about PCBs in the music industry.

PCBs are foundational features for many electronic components in music. The boards hold electrical components in place and let electrical currents flow, powering musical hardware for musicians.

Many PCBs use fiberglass or similar materials to hold electric currents. Copper lines let charges move around the layer in the designed pattern. PCBs vary in shape and size to best fit the application at hand.

Musicians and other professionals in the music industry use PCBs in many pieces of music hardware. Here are some examples:

Amplifiers are crucial tools within the music industry. They’re available in electronic formats with PCBs and in hand-wired forms. Hand-wired amps are also known as point-to-point (PTP) amps. Many musicians have different preferences between them.

To understand the differences between the two options, it’s best to learn how they individually function.

Here are overviews of both amplifier types:

If you are deciding between PCB vs. point-to-point, consider your preferences. For example, a guitar amp PCB layout might suit you better than a hand-wired one. It’s also helpful to think about the pros and cons of both amp types. Each option has characteristics you might prefer or dislike.

PCB amps feature advantages like:

Once you put a PCB together, it’s challenging to take it apart and rework it. If an electrical component fails, it’s harder to directly address the issue because of the construction process.

On the other hand, hand-wired amps have pros like:

Building a hand-wired amp takes high skill levels and longer amounts of time than PCBs. If you need your amp quickly, a PCB might suit you better. The long labor hours and need for skilled technicians also make the point-to-point process more costly.

Both PCB and PTP amps have benefits and disadvantages. When choosing between the two, musicians often go with their personal preferences for feel or sound. You might also choose the best option for your budget or want to match new equipment to your existing inventory. Whichever you choose, know that both are excellent options for sound projection and can fit a variety of uses throughout the music industry.

Printed circuit boards are an integral component of the music industry. From servicing various electronic instruments to acting as a building block for tools like amplifiers, PCBs help the music industry function.

If you’re seeking a PCB, consider Electronic Manufacturing Services Group, Inc. Our high-quality PCB boards serve a wide range of industries, from the medical industry to telecommunications to colleges and universities. We set apart from competitors by focusing on customer satisfaction and superior value.

As a full-service printed circuit board assembly company, we offer these PCB setup options:

If you’re interested in Electronic Manufacturing Services Group’s PCB services, contact us today. One of our knowledgeable representatives will get in touch with you and start working on your tailored project!